“Can’t we just lay some decking already?!” That quote’s an homage to this kitchen post from last December about all of the little annoying prep steps we had to squeeze in before we could get down to painting cabinets – and I feel like we just hit the same stage in the deck project. Which means we’re making progress, but we’re impatient little DIYers. After getting all of the joists set in place we were soooo excited to finally lay down the decking… until I realized I had a bunch of nitty gritty details to take care of first. Womp womp. But not to worry, you’ll actually see decking going down at the end of this post (and that process continues – wahoo!) so we’re a lot closer to the end of this project than the beginning. Whew.

The first item was actually getting an inspection. A voluntary one at that. Shocking, I know. Technically our next mandatory inspection from the county was a final one, once everything was complete. Call us insecure, but the idea of finishing the whole thing only to find out we’d made a mistake at this stage (and thus having to undo lots and lots of stuff) gave us cold sweats. So Sherry called the county and found out we could have an optional “framing inspection” just to make sure we were on the right course. Yes, please.

I’ll spare you the suspense – we passed. Though technically I made a minor error by notching my 4 x 4 posts (see below). Our county only allows notching of 6 x 6 posts. If you use 4 x 4s like me you’re supposed to attach to the top of the post with special bracket. But this inspector (a different guy from the first two) was sympathetic to the fact that I had already done it – and acknowledged that their instructions aren’t 100% clear on this point. I guess it’s more important when the deck is bigger, higher, and will be holding more weight, but since ours is just a few feet from the ground and only 8 feet wide he wasn’t worried at all. I’ll share a quote from him (probably my favorite thing I heard all day): “this thing’ll hold up five elephants and about 500 of those (points to Clara through window).”

In short: assuming we’re not planning on hosting the circus anytime soon (or a party with 499 of Clara’s closest toddler friends in attendance) he was happy to give us the okay to proceed. These inspectors seem to be getting nicer each time. Maybe the next one will bring me cookies?

So proceed I did. My first task? Completing the framing around my joists by adding the two band boards that would finish off the exposed edge of the deck that currently sported some uneven joists just dangling over the edge.

This is the angled portion of our deck (where the stairs will lead down from it) so it took some special attention – and more than a few miter cuts. My first task was to cut off the excess portion of the two joists so that I could attach another 2×8 to the end. So I held a nylon string in place to help me mark where my 45-degree angle would go.

With my tops marked, I used my “Ross Gellar” Pivot ruler to mark where I needed to slice my joists at an angle.

My circular saw can do angled cuts just by adjusting the saw’s table, so I was able to cut these two joists in place. Note: this isn’t actually how I hold the saw when I cut (since my hand is nowhere near the trigger) – it’s just the only way I could hold it and take a picture at the same time. So yes, let’s call this a bad reenactment.

Here are my two boards cut at the angle.

Then I took the 2 x 8 that would act as my band board across the two cut joists and cut it to size – including an angled cut on one end where it would rest against the house at an angle.

Here it is all in place. To actually get it there I balanced it on one hand while I temporarily hammered it in place with the other (using some nails I set in place before holding it up). Once the nails had it in place I secured it with screws.

So that was all fine and dandy for finishing one edge. But I still had this open end that needed a board of its own.

So I started off by cutting another 2 x 8 to size – once again with a mitered cut on the end so it would rest flush with the board I just finished attaching. It’s just resting loosely in place in this shot below:

Because before I attached it I realized I needed to trim the girders that it was resting on because they were too long and they stuck out the edge. I did this intentionally when putting the girders in because I knew I could always cut off excess inches, but adding it back would be tough.

I used my circular saw to cut them most of the way through, and then finished off with my reciprocating saw (since my circular saw doesn’t cut deep enough to go through two 2 x 10s).

Then I was able to set my board in place (resting on the edges of girders) and screw into the rim board against the brick and the angled band board.

And once I cut the excess off of the angled band board I was finally getting the finished edges that I was looking for.

With the end of the deck looking better, I turned my attention to my next nitty gritty task: adding counter flashing. If you recall, one of the conditions of leaving my ledger boards (the ones that caused me to fail my first inspection) was to add this additional flashing over the tops of the boards.

On the siding side, I just slid the flashing up under the bottom piece of siding and nailed it in a few places like before. On the brick side I also repeated my process of folding over a small piece and then stuffing it into the crevice I cut in the mortar (the same crevice the original flashing also went into).

Once this was in place I used scissors to cut the vinyl to go around the joists. The idea here is that the counter-flashing will further protect moisture from damaging the ledger boards and the house by directing water away from both. And you can see on the far right how I folded up a small lip at the bottom of the flashing to be sure the water drips away from the brick.

To keep the flashing in place on the brick side I also ran a line of clear silicone caulk in the crack. Not only does it act like a glue to keep the flashing in place, it also keeps moisture from collecting in the crevice.

The flashing was more tedious than it was difficult, but I was still happy to have it done and be one step closer to putting in my deck boards.

I was just about to start on the deck boards when I realized one other task that was worth thinking through while the “bones” of our deck were still exposed: the stairs and railing. This whole time I’ve sort had a “I’ll cross that bridge when I come to it” attitude towards the stairs and railing. And suddenly I found myself at that bridge. After all, if I was going to have to add any special reinforcements or attachments to secure the stairs or railings I figured it was easier to do that now.

So I started off by figuring out where the stairs would attach and where I’d need to put in guard rail posts. I borrowed two spare 2 x 10s to act as my stair placeholders (based on the placement of the already-dug holes for my stair posts).

That helped me determine where the posts needed to go on the deck itself. I’ve decided to do the stair railing “inside” the stair stringers so that the steps kind of wrap around the posts a bit.

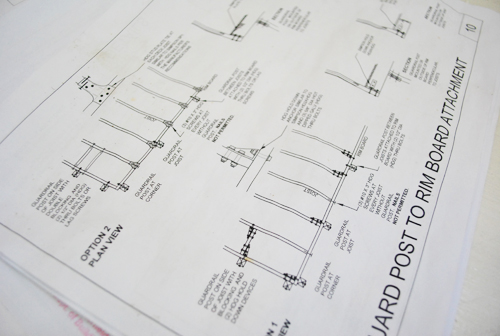

Once I was able to mark where each of my 4 x 4 rail posts would go, I had to determine how they’d be attached. Fortunately, the instructions provided by my county were super easy to understand.

I can not emphasize enough how sarcastic that last sentence was. I stared at the page for what seemed like days trying to figure out what it was telling me to do. Then I called Sherry over who was just as confused as I was. Part of our confusion came from the fact that nothing indicated what to do with the angle we had. And we couldn’t find any of the products they suggested on the sheet.

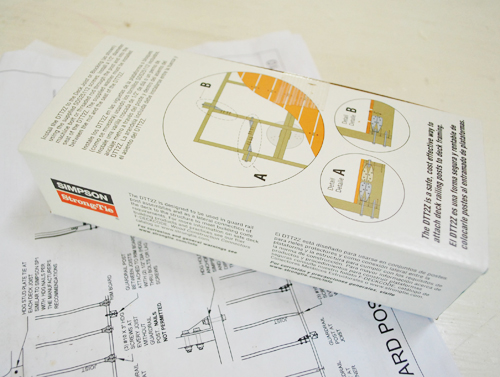

But we finally found these Deck Tension Ties on our third trip to Home Depot (after overlooking them on the first two) and this Deck Magazine article that gave me some sort of indication as to how to deal with my angle situation.

My understanding is that the old system of just bolting a guard posts to the outside of your deck is no longer considered as secure as it should be. That same Deck Magazine article explains it better than I should attempt to (there’s a reason I’m not an engineer) but I just trusted that these would help me pass inspection and keep my railing from folding over when we lean on it. You can see below how it got screwed to the rim board against the house.

Then I drilled a matching hole in my 4 x 4 post (which I had already cut to meet the 36″ railing height requirement in our county) along with a second hole below it.

Then I used two 1/2″ bolts to attach the post to the deck – the top one going through the tension tie. It felt very secure, so I’m thinking (hoping?) this is an inspection-passing guard rail I’m starting to make.

But of course I have more than one post to install. And the others – which wouldn’t be right against the rim board attached to the house – required some additional blocking. You can see below how I added a piece of scrap 2 x 8 between the two joists (which I secured with screws) and then bolted a tension tie to either side of it. That’s known as additional blocking.

I decided not to actually attach any more posts yet (since I though they’d only get in the way as I install deck boards) but I wanted to get all of the hardware in place while I could still easily access everything from the top. So without bolting the next post in place, I moved on to adding the extra blocking and tension ties for my two posts on the angled portion of the deck.

Here’s what it looked like by the end of it all. You can see I also added some hangers where my joists met the angled band board. I’m not sure they were necessary, but they made me feel better about it. Maybe now this deck can hold six elephants?

I realize my glossed-over description of making these preparations for the guard rail may make it seem like an easy, speedy task. But it actually took me two days of work to complete. Partially because none of my power tools would fit into the small spaces, so I had to do a lot of the screwing and bolting by hand. But it also took so long because of the weather. Yep, just when I had become accustomed to working in extreme heat I now have been enjoying pop-up thunderstorms that have cut more than one afternoon of work short. And although we’d be faster with Sherry on the case, we have lots of book stuff due, so when she’s not blogging and watching Clara (for example, when the bean’s napping) there’s book proofing and a pretty detailed resource section at the back of it to compile.

But even though the thunderstorms are delaying my progress, they’re definitely not stopping it. In fact, I’ve finally gotten some actual deck boards down. And since you’ve patiently endured this otherwise not-very-exciting post, I give you a little bit of visible progress to hold you over until I can make more progress and come back next week with some more oooh-and-ahhh-worthy photos. Oh yeah, we’re going all out when it comes to the board layout. Not only are we mitering the corners to create one big frame around the entire deck, we’re also adding a few zipper-like seams with the boards (first mentioned here). So far we love how it’s turning out. Can’t wait to get more done and share the pics!

Now that we’re finally getting somewhere, all this work is starting to pay off. It’s about time, right?

So what nitty-gritty / annoying / unglorious tasks have you tackled recently? Have you finally done those paint touch ups you’ve been putting off? Switched all the batteries in your smoke detectors? Weeded your patio? Replaced your air filters? Oh man, this is starting to sound like my to-do list…

Meagan {Green Motherhood} says

John, I have no idea what you are talking about in 3/4ths of this post, but call me impressed. Great job! Can’t wait to see what you are doing this week. :)

Ofelia, México City says

Oh man, what a nice work! It looks like endless hours of labor… Your skills are fantastic. I, finally, just paint two little tables, one end-table and a coffe-table, last week. Nothing hard, but sanding under the sun at 30ºC here at tropics, is definitelly, awkward!

Sarah T says

I must vent about what I’m up to…MOVING! Last night it took nearly 3 hours to get our couch up to our second floor apartment. A hack saw was involved when the corners got too tight. Yes, we had to saw a part of the bottom of the couch to squeeze it through the door. And now that it’s in, we get to fix it!

I’m probably as exhausted as you.

YoungHouseLove says

Wahoo! That’s so exciting! I know it’s so tiring, but it’s so fun to have a new space! I hope it all goes smoothly!

xo,

s

amz says

Oh man, I was planning on surprising you guys with a “Yay the Deck’s Finished!” party and bringing along my six elephants :(

The sneak peek looks amazing, can’t wait to see the end results!!

YoungHouseLove says

Haha, let’s downgrade to five elephants and all will be well!

xo,

s

Lynn @ Our Useful Hands says

Whaaat? Yeaaaah!!! <—lil jon style! Even though my eyes kind of glass over when you get all mathy on us (haha!) I can tell that you are putting alot of your sweat and…sweat into this project and it's so cool that you will eventually be able to throw the most epic and then tragic elephant/toddler party the world has ever known.

My best, Lynn

*I totally fell for the sentence "the instructions provided by my county were super easy to understand." I was like "Awww that's always nice. Their town is so Truman Show."

Lynn @ Our Useful Hands says

I dont mean I get glassy eyed so don’t bother writing all that ESSENTIAL INFORMATION, I mean I still enjoy all the in’s-and-outs and appreciate it because one day we will be possibly at this point in our outdoor home improvement and I will be poring over all these thorough posts like an appreciative human and thanking my stars that I “know” someone in the “industry” to walk us through it all. ;o)

My best, Lynn

how2home says

Question for you John! Were you always interested in learning how to do DIY? How and where did you learn how to do these projects ….indoor and outdoor stuff?

YoungHouseLove says

No, not really. I mean, I’ve always enjoyed creative tasks but beyond like things like Lego’s and Kinex growing up, I can’t say I had the DIY bug for a while. Most of the information I’ve gotten for any project has been online – whether through expert tutorials on sites like Lowe’s, Home Depot, DIYNetwork, etc or other home improvement bloggers who have tackled the same stuff. It’s always fun to mix the straight how-to sites with personal experiences.

-John

Annie says

Hey, thumbs [this] up if you read just the first paragraph and scrolled down to the end! Teehee.

Katie says

Haha. Paint touch-ups: check. Batteries in the smoke detector: check. Replace air filter: check. You’re making me feel guilty about the weeding, but hopefully this weekend we’ll get around to that :)

Chrissie says

John, I have to ask, do you have some kind of problem with my laptop? Because your “maybe the next one will bring me cookies” comment nearly made me spit water all over the poor thing! It’s my own fault really, I should have learned by now not to eat or drink while reading posts here.

At least my laptop would probably be more forgiving than my coworker was that one time at work drinks… awkward. Good thing he had a sense of humour!

Seriously though, I am in awe of how much work is going into this (and secretly glad we changed our minds about building a deck here). It is looking incredible already, I bet you can’t wait to see the finished product!

Barbara says

That thing is awesome!! Wish I could hire you’all to lay new flooring here and install a new toilet. I even have a nice balcony window that Clara could look out and ponder our ducks while you’re working!!

Can’t wait to see the final pictures … when it’s all gold-plated and furnished :HUGE SNICKER:

Barb

Koliti says

Wow! Talk about problem solving skills, math skills and perseverance! Whew! Think about all of those new brain cell connections you’ve created.

Love the “zipper” board alignment.

Didja notice that it mimics the pattern of how the ends of the bricks line up from row to row on your house? Same square undulating effect. Nice.

YoungHouseLove says

Oh yeah! That’s neat!

xo,

s

Melissa B. says

Great job Guys!! We’ve been working on a deck project here pretty much concurrent with yours. I’ll admit it, yours is going faster…and yeah, I’ll admit it… we ended up hiring out the concrete/posts/structure/house attachment part. What can I say – my deck is 14 feet off the ground! Anyway, 1 tip and 1 question. Tip: Check out this site for deck finish/stain reviews: http://www.deckstainhelp.com/category/deck-product-reviews/ . Upon their recommendation I went for Armstrong Clark brand finish, but like you I have to wait a couple months to apply. And Question: can you give a little more information about those Deck Tension Ties? All I could find was seismic restraint ties and they were about $30 A PIECE (x 30-40 ties)! Again, great job! I’m so impressed with your progress – through heat, inspections, time constraints, etc. And Sherry – I’m TOTALLY looking forward to the Mood Board for the deck!

YoungHouseLove says

We just found them at Home Depot, and they were in the section with all of the exposed Simpson brand deck ties and hangers, but they were in a box (I think each box was $15 but it had two ties in it). I needed 7 total. Hope it helps!

-John

Krissy H says

Regarding “crossing the bridge” that would be your stairs and railing…

I’m always so fascinated and impressed by a person’s ability to foresee potential challenges in carpentry/construction projects BEFORE the entire project is complete ! My husband and I have taken on a huge DIY home reno project; where after several weeks on a particular project/room, I can see the finish line and in my excitement I just want to “get it done”…but he has the patience to visualize, assess, and tackle a potential “trouble-spot” that wouldn’t have occurred to me until after the project was complete. It ends up taking a little longer, but ALWAYS so worth the due diligence! (After living several months in chaos – what’s another few days especially when it’s done right the first time?)

You guys are great! Thanks for keeping us (me) motivated!

Amber says

The deck is looking great! I am excited for future posts about table settings for fun family gatherings. And I think Clara is going to be pretty excited about getting to walk on it instead of look at it through the sliding glass door!

We are getting ready to start our own deck overhaul and these posts are giving me heart palpitations! I know we can do it, but I think we had that whole, ‘it will take a week MAX’ attitude. I’d love to forward your entire list of deck posts to my husband to give him an idea of the process you have gone through to this point. Are those collected anywhere on the site (the list of links to individual posts)? Or can you remind me when you started this whole process so that I can go through and find them all?

Thanks! Can’t wait to see the finished product. =)

A

Sonya says

The quote from the inspector made me laugh out loud calling Clara “…500 of those”. The way she watches through the window is too cute, she certainly seems to be enthralled with the whole building process.

Jaye @ Just Trying to Make Cents of it All says

Your projects sound like ours…it’s always something more that has to be done/fixed/straightened/painted, etc. before the “real” fun begins! It’s looking awesome though.

Marian says

THe frame and zipper seams look SO cool! How awesome. But the only thing I have finally gotten around to was removing candle wax that has been stuck to my carpet for two years. I kept looking at it and wishing I could get to it, and one day last week I just did. Silly, but nice to have it gone.

YoungHouseLove says

Haha- that’s amazing! Two years and now it’s gone! I bet it feels awesome.

xo,

s

Jesse says

Dang! Lookin good you guys! A deck ads so much to a house. This is a dumb question, but I can’t figure it out, what are you using to put the bolts in? I feel like there must be something other than a drill…

I have yet to build a deck, and haven’t used bolts for anything, so I’m clueless, haha. Thanks!

YoungHouseLove says

I’m using a socket wrench to tighten those bolts (manually). It’s not that bad though. Just a lot of turning! Haha.

-John

Peg says

All I’m gonna say is you have infinite more patience than I do…sure you’ll love it when it’s finished!

Steve says

John,

For as much as you use a drill you should really consider getting the new Makita ones. I held off for a long time but was absolutely amazed when I got one. The little impact drill is seriously crazy. You would love them.

Steve

YoungHouseLove says

Sounds awesome. Thanks Steve.

-John

Kim S says

Speaking of tedious, nitty-gritty tasks…a little over a year ago we laid Mexican beach pebbles and a few “stepping stone” pavers between our carport and the backyard fence. It’s not a huge area, probably just a 4 x 15ish ft strip. It really spiffed up the carport area, which is nice because we use it as an outdoor entertaining spot when we have friends over. However, over the past year a lot of debris fell in between the pebbles, and then this summer a TON of weeds popped up, so we’re currently in the process of taking ALL the rocks out so we can rinse them, rake the debris up, and lay weed-blocking fabric to hopefully avoid doing this same time-consuming task next year!

YoungHouseLove says

Ugh! That’s a lot of work! Good luck!

xo,

s

Laura says

hahahaha. I have to share this.

I used to work for a home repair ministry, Appalachia Service Project, where I spent four summers in WV and VA coordinating and supervising construction projects being carried out by volunteers. During my four summers with them I had my fair share of visits with building inspectors and dealing with county regulations and guidelines for the region (we actually built quite a few decks and wheel chair ramps). Anyway, when I read your sentence, “Fortunately, the instructions provided by my county were super easy to understand,” and then looked at the picture, I thought to myself, I wonder if he is being serious. Then I read your next sentence, “I can not emphasize enough how sarcastic that last sentence was,” and I almost died laughing.

That’s good stuff! I love your blog and your writing styles. Thanks for the enjoyment!

Tris says

Here’s some advice from my other half who is also enjoying reading about this project (we’ll be doing something similar soon hopefully!).

Enjoyable read. Not sure if you can comment on their blog but if you can it might be worth mentioning that they need to leave a gap between the boards to allow for expansion. As the timber gets wet it grows width ways and without a gap being left the boards will cup. Wish them luck from me..

YoungHouseLove says

Thanks Tris! Check out the top of this post for that info (maybe it varies by area, but here pressure treated boards shrink up, so gaps will be created – but they won’t expand any more).

xo,

s