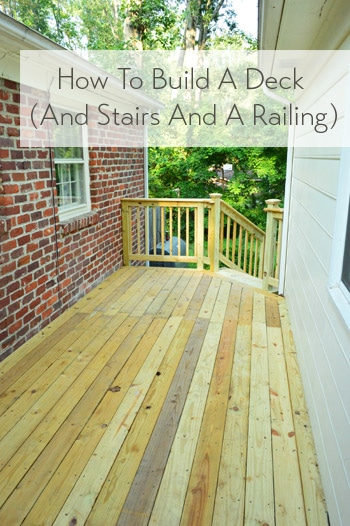

The deck is officially done. Sound the celebratory cowbells! I actually finished it on Friday and we’ve spent the last few days crossing all appendages and waiting for an inspection (I couldn’t bear to share my triumph until I was actually sure it was a to-code triumph). The inspection finally happened yesterday afternoon, and – ta-da! – we passed. Relief flooded over me like all the sweat that I put into building this thing (lesson learned: build decks in the spring or fall). Here she is in all of her wood-riddled, approved-by-the-county glory:

It’s definitely an upgrade from the tiny rotting balcony that we started with:

We thought it’d be great to have it done when Sherry’s mom came to visit from NY today, so I put my head down, powered ahead, and sweated through my belt for one last leg of this deck building marathon.

Admittedly it was a bit more of a marathon than I expected. We originally thought this deck would take us three or four weeks of on and off work to complete, but between the heat, thunderstorms, inspections, equipment rentals, material deliveries, summer travel (we ended up being gone more than half of the weekends since starting) and generally being a one-man show who has never built a deck before… it took ten weeks instead. But that doesn’t make the victory any less sweet to me.

I actually kind of enjoyed having an excuse to go outside (despite the extreme weather) and tinker around with something during the occasional Clara nap or Saturday morning. It was weirdly peaceful – getting to ignore emails and diapers for a few hours and just saw stuff. And of course having my dad’s help with the auger when it came to digging those post holes was the best. Nothing like a father/son project to get the serotonin pumping.

So if you’re wondering how long a deck project could take, I think an experienced team could knock something like this out in a week (you’d need a few days to pause for inspections in our area, so a weekend wouldn’t do it). But if you’re doing it almost entirely alone as a first-timer, and can’t work all day every day (maybe you can devote a few afternoons or evenings during the week and a day or two every other weekend like I did) it might realistically take you a month or two – depending how inspections go, if it’s raining for two weeks straight, etc. But I can promise you one thing: there’s an insane amount of satisfaction when you sink that last screw.

Now let’s rewind for a moment and I’ll try to breeze through how I got the stairs and the railing done. Once all of the decking was laid down, I cut and attached the remainder of my four posts (you can read more on how I did that in this post).

Even though the stairs were next on my list, getting the railing posts up was important to help me plan the stair stringers – which are the diagonal boards that run down the side of the staircase, where the steps actually rest.

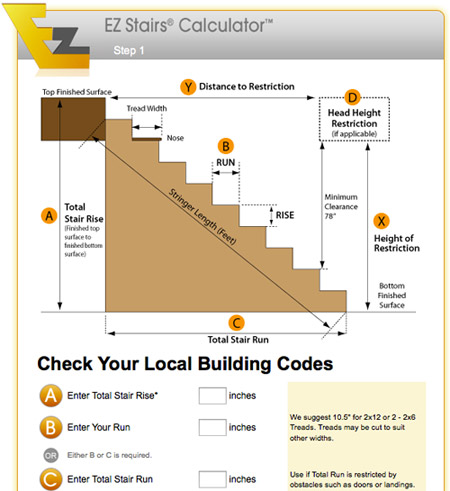

You can buy pre-cut stringers, but I tackled cutting my own (to save money and time since that’s the lumber they provided in our delivery). Figuring out the lengths and angles of everything was kinda scary until I found this website that did most of the math for you. Thank goodness for the world wide web.

Once I had my rise (the height of each step) and run (the width of each step) calculated, I learned a cool trick from this video for marking your 2 x 12″ board for cutting. I basically clamped a straight edge (in my case, a piece of scrap wood) to a framing square (the L-shaped ruler) so it intersected at my measured rise and run. Then I could hold the scrap wood flush against my board and the framing square would create a perfect guide for marking my cuts:

With the length of my board marked, I broke out my circular saw and carefully cut along the lines.

You’ll notice above that despite looking cut from above in that last picture, the triangular pieces weren’t falling away. That’s because the circular-shape of a circular saw doesn’t always allow you to reach those deep corners all the way through. So I went back with my reciprocating saw to finish the cuts all the way.

Once one stringer had been cut (and tested in place to make sure it fit) I used it as a guide to mark and cut two more 2 x 12 boards, since I’d need 3 total stringers for my 48″ wide steps.

So here are my three cut stringers in place. You’ll notice the one in the middle has a weird extra piece in its center. That’s because a not-so-conveniently located knot in the wood caused the tip of one step to break off. Rather than go buy (and re-cut another whole board) I just patched it by cutting and screwing a short piece of wood to patch it (making sure it would be to code first).

To attach the stringers to the deck I used these angled hangers that I snagged at Home Depot.

Oh yeah, and I was sure to check that the steps were level the whole way down. Don’t want wonky steps now, do we?

Speaking of wonky, I did install some blocking between the stringers. They weren’t perfectly level themselves, but they’ll be completely hidden, so that’s okay. The point was that by using equal sized scrap boards the blocks still served their purpose of keeping the steps an equal width the whole way down (we didn’t want the steps getting subtly narrower or wider on the way down).

Next came setting the posts that would support the staircase in the middle and the bottom (using the footing holes that I dug back when I started the deck). To attach these posts, I decided to use these anchors I found at Home Depot this time around.

I basically set them in some wet concrete (after carefully marking where they needed to go to line up with my steps – which admittedly was a somewhat maddening process). Then I let them dry.

Since my concrete needed 4 hours to cure, I filled some of that time by beginning to cut the wood for the steps. We wanted the steps to match the decking, so we used two 2 x 6″ boards for the base of each step (which included a small overhang) and a 2 x 8″ board for the back of each step.

Once my concrete was dry and my post anchors were solidly in place, I set my posts, checked that they were level, and nailed them into place. You can see this anchor was not 100% exact in its placement – but that’s part of the reason they’re open on one end. That wiggle room was a lifesaver.

So here are all of my posts set (but not cut to size yet) and a random assortment of step boards just loosely laid in place. Looks kinda like a staircase. Looks kinda like a hot mess too.

Oh yeah, and I bolted the posts to my stringers the same way I bolted the railings to the end of the deck.

Then came the task of screwing all of the step boards into place. This task took surprisingly long and a surprising amount of screws.

With all of the stair boards in place, I turned my attention to the guardrail. The first two parts of the guardrail were the 2 x 4″ rail boards that would span between the posts on the top and bottom. Our county requires no more than 4″ gap between the deck and the rail (it’s also known as a sweep space, so you can easily sweep debris off the deck). I saw someone use a 4 x 4″ post as a guide for this since it’s an easy way to keep the rail level so I did the same thing. Worked like a charm.

Attaching the railings to the stairs was a bit more involved since I had to make sure I was meeting several standards for how much of a gap was at the bottom and how high it had to be compared to the nose of each tread. Once I had figured all of that out, just cutting the angles and keeping things in place while I screwed it all together made my brain hurt a little. But eventually I got all of the railing pieces in place.

Oh, and you may notice that the four posts attached to the deck got significantly taller. I had to replace my original posts because I realized too late that I had cut them too short to satisfy the railing height requirements on the steps. It’s a long story so I’ll just leave it this: it kinda sucked and that’s why it’s nighttime when this photo was taken. Oh well live and learn. They weren’t going to be staying that tall, but after replacing them once I decided this next time that I’d cut them in place once I was certain my railing height would pass inspection – just to avoid any more surprise do-overs.

The next day I could finally start putting the balusters in. Those are the vertical pieces on a standard deck railing. We debated doing something more intricate or modern (like all horizontal rails or a built in planter) but opted for the traditional look because that’s what we have out on the patio side of the house (there’s a fence and a railing out there). Both that railing and this one are visible from the living room (out various sliding doors) so we wanted them to match. I’m also glad we went the traditional route because it was super easy to do (since I could use my post as a guide to meet the spacing requirements again).

The last part of the guardrail is the rail cap, which is the flat ledge on the top. It’s made from a 5/4 x 6″ decking board. Cutting those angles and notches around the posts was an adventure too, but I won’t bother you with the details. In short: I lived to tell the tale!

Oh yeah, and you can see now that I eventually cut all of my posts down to size when I was sure they all met code. Thank you reciprocating saw for that.

When it came to attaching the balusters to the stair railing, I didn’t even attempt to pre-cut them to size like I did on the other railing. Instead I temporarily removed the rail cap I had cut and screwed the balusters into place with the excess length extending out the top. Then I used my reciprocating saw to cut them down so the rail cap would sit flush again on top of them for a finished edge.

With the balusters in and rail cap back on, I started putting the finishing touches into place – like this handrail that we’re required to add since our stairs have more than three steps.

And we added these decorative wood caps ($8 at Home Depot) to the posts at the top and bottom of the stairs. They attached with just a little bit of caulk and definitely make things look nice and finished.

And with that, the railings – and therefore the steps – and therefore the entire deck itself… was finally done!

I have to admit, I’m still kind of impressed that I made this.

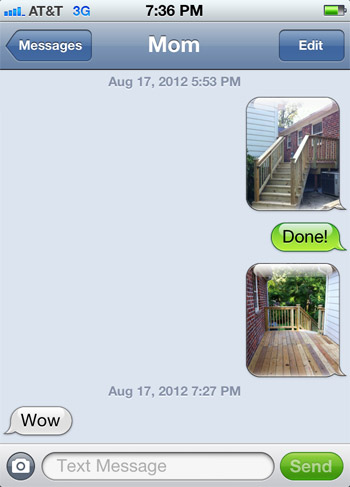

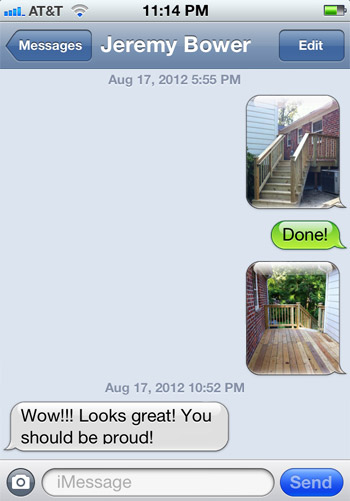

And what do you do when you’re proud of the deck you just built? Naturally, you text your mom.

Well, your mom and your bro-friend.

Although being totally built and county approved doesn’t mean it’s totally done. We still need to seal it (we’ll be tackling that as soon as we catch our breath and research the right product for the job) and of course we need to furnish it. As for the budget breakdown, once we seal it we’ll share the full rundown. Until then, you can find me sitting out on the deck, sans furniture, drinking a nice cold soda. Or telling Sherry that I’m not building another deck for at least ten years. Yes sireee, I’m glad to have this done. Although to anyone wondering, I still think demoing our first house’s bathroom and rebuilding that from the studs was the hardest project I’ve ever done. But the deck is hanging in there at second place. Anyone else finishing a deck or some other project that took longer than you expected but is still intensely satisfying to have checked off the ol’ list?

Psst- Want all the deck details? Here’s where we shared our vision for the space, removed the plantings and the old balcony, selected our materials and documented our first day of building. Then we dug our post holes, failed our first inspection, revised our plan/dug more holes, and set posts. Then we installed our joists, did some last minute prep for deck boards, started laying decking boards, whipped up a mood board and finished laying deck boards.

amy c says

This is amazing John. It’s a beautiful deck. Even though you have done a wonderful job explaining every step, I’m pretty sure it’s safe to say, deck building is not in my future. So much work! And I like projects. Thanks for sharing.

Again, amazing job. Well done.

Cynthia says

Your deck looks AWESOME!!! Great job!!!

Janice says

Amazing job. I just told my husband I want him to start on making out deck bigger after seeing yours. He said maybe when the weather cools down some.

Mary K says

Apparently a week without the internet was too long. I can’t believe I missed your deck reveal!

I know from strangers it doesn’t mean as much but I’m so proud of John for getting it done!! And woodworking projects with so many complex facets are just that much more impressive once complete. Sorry I didn’t get to congratulate you sooner, but you guys are awesome and such an inspiration. YAY DECK!!

YoungHouseLove says

Aw, thanks Mary!

-John

Leslie F. says

The deck looks great! I wanted to recommend a sealant that I came across researching sealants for cold frames and a solar kiln. I wanted something as non-toxic as possible and I stumbled across something called Seal Once (http://www.seal-once.com/eco-friendly/waterproof-wood-sealant). I haven’t actually used it since we have yet to build the aforementioned projects but am planning to use this product when we do. You have to order online or pick it up at one of their retailers, I think the closest retailer is somewhere near Baltimore. If you don’t mind ordering online or travelling to get a good product it might be worth a try!

YoungHouseLove says

Thanks for the tip Leslie!

xo

s

Kimberly Hall says

I’m so proud of you as well! You did a very great job here and I’m amaze that you did this alone. Anyway, your post caps are cute. It is nice that you put those caps on your post, it adds beauty to the entire deck. It’s just beautiful.

kelly says

Thank you so much for posting. The deck looks really nice.

kr

Melissa says

Hello! Quick question for your regarding the deck railings. Did you attached the railings to the post with just a deck screw? We are adding railings to our deck now and are not sure where to use a bracket or just screws. The brackets are not esthetically pleasing and cost a fortune so I would rather not use them.

Thanks!

YoungHouseLove says

We used some Deck Tension Ties on the inside of the posts because my understand was that just bolting to the outside wasn’t strong enough. If you scroll to the end of this post: https://www.younghouselove.com/2012/07/can-we-just-lay-some-darn-decking-already/ you’ll see how I attached them so they’re hidden under the decking. Good luck!

-John