Yes, this is a post about how to run dryer duct work and reroute HVAC vents. Why would I make a horribly punny reference to a 22-year-old Disney hockey movie if it weren’t? But first, some background. By the time Monday’s post was going up, David the framer was here putting the finishing touches on our new laundry room by adding that fourth and final wall (the one that will have the door that leads to the hallway).

He also added the wall that will eventually house the frosted door to the current storage / future TV room. I took the picture from this side to get around that lovely plastic sheet, which helps us keep some of the attic heat at bay.

Here’s a full shot of the completed framing. I propped up the door just to give everyone an idea of how much it will swing into the room (it’s 8′ deep, so there’s plenty of room for that door to swing without interfering with our washer/dryer/cabinetry).

But this post isn’t really about framing, it’s about some of those little annoying tasks that you sometimes forget about in all of the excitement of a big project. Annoying, but no less important. So here are the three items we checked off our list before drywall could begin. They’re not the most exciting, but I hate to skip over them for anyone else facing similar projects… so prepare yourself for lots of photos coming your way.

Let’s start with the new dryer vent. I read that for proper function (i.e. getting clothes dry and not starting lint fires) a dryer vent pipe should be no longer than 25 feet and for every 90-degree turn, you should subtract 5 feet from your length. Here’s what our old set-up looked like, which I think was about 10 feet too long or had about 3 too many turns in it.

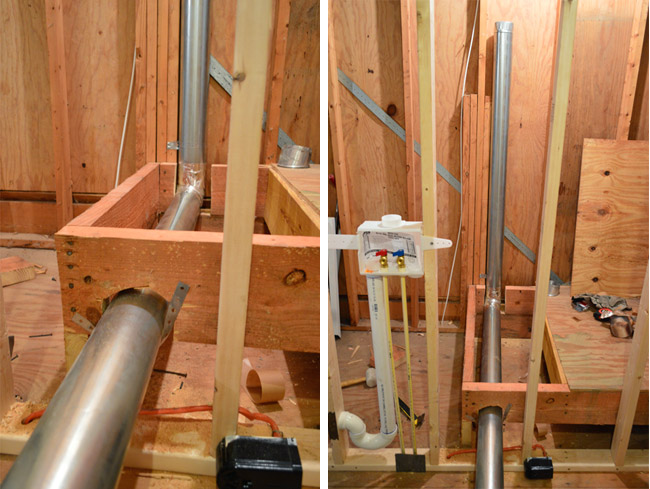

The good news is that by putting our dyer on the back wall of the new room, we were much closer to the exterior wall. But when we initially mapped out where the new vent could go (Plan A) it wasn’t faring much better. To keep the pipes up and out of the way, it took nearly as many turns and almost as much length. Boo. So we found a new path (Plan B) that was MUCH better and shorter by going under the attic steps… only it involved cutting a new hole in the exterior wall. That doesn’t top my list of fun activities, but it had to be done. And I’ll explain later why we chose to still take it up the wall rather than exiting the house under the stairs.

To start, I needed to make a path under the step for the 4″ vent pipe to go. I used my Dremel Sawmax to cut the plywood top along the step joist so that I could easily reattach it later. Then I used a reciprocating saw to cut a 4″ wide section out of the 2×6″ for the vent to rest in.

I was planning on reusing the existing metal vent pipes since they were in good enough condition and I had a lot of pieces to choose from. All they needed was a good cleaning first, which I did by taking them all apart and using a long bristled brush to scrape them clean along with my Shop Vac.

Then I started piecing them back together. Pipes like these have a crimped end that makes them easier to fit together. I read once that you want your crimped ends facing the same direction of the airflow so that air doesn’t escape around the crimping. Once fitted together, I sealed everything with metal-faced duct tape (note: not duck tape!).

Once I had all of my pipes fitted together, I started to position them to run them under the stairs and up the back/exterior wall. You can see that I made an opening in the side of the step for the duct to pass through there, and I held everything in place with some steel hanger straps.

That bottom pipe extended way too far into the room, so I cut it down using my metal snips. I left it a little long so that I can cut it to its final size once the room is more finished. The green painters tape is just so we don’t cut ourselves on the raw edge while working.

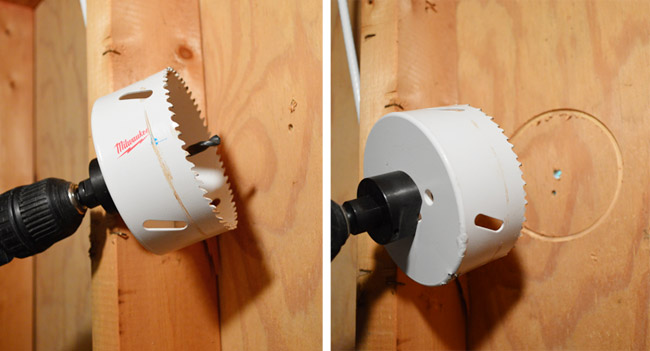

Next up was putting the new hole in the exterior wall. Fun. I started off by drilling a pilot hole from the inside to mark roughly where the new vent hole needed to go. This was mainly to make sure I placed the hole directly above the pipe that I just installed.

Then I headed outside to start making the big hole in the siding. More fun. Especially the ladder part. Yay. Anyways… I did this using a 4 1/8″ hole saw (which you’ll see closer in a moment). I wanted to start from the outside to make sure I was placing it in the middle of a siding board (and not awkwardly spanning two of them). The pilot hole I made from the inside helped me make sure I was drilling in the right spot.

Outside I only made it through the hardboard siding (not the plywood beneath it). I didn’t want to spend any more time up on that ladder than I had to, so I came back inside to do the rest. The 4 1/8″ hole saw bit made a fresh pilot hole for me to follow so I could be sure everything lined up.

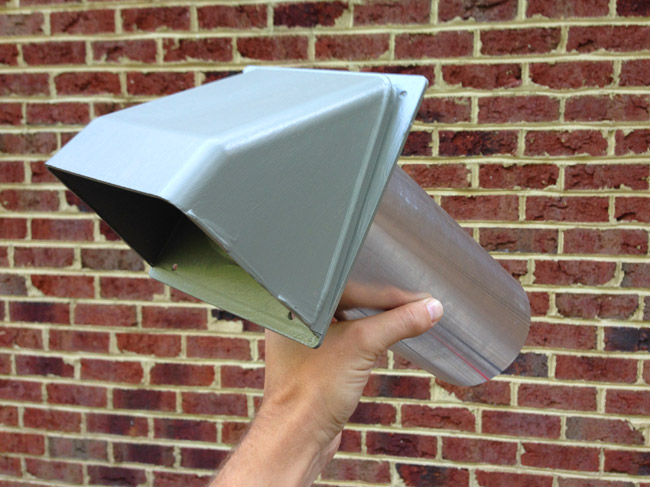

With the hole cut all the way through, I could install the new dryer vent on the outside. I bought one that resembled the original one, since they’ll both be living up there until we go through the trouble of removing the old one and patching the siding (we’ve just capped and sealed it from the inside for now). Oh and Sherry painted the new one to match the siding before I installed it so there’d be less work to do up on the ladder.

Before climbing up I put a ring of silicone caulk around the back of it, that way it’d have a nice weather tight seal from the get -go.

It took a bit of finagling to get it in (the 4 1/8″ hole took some sanding down to get the 4″ pipe through) but eventually it was in and I could screw it to the siding for a nice firm hold. And this photo shows why we chose to put the new vent as high as we did, rather than exiting the house under the attic stairs. That would’ve put the vent barely above that bit of roof below, meaning lint would’ve built up on the shingles. So because we had to take it higher no matter what, we figured we’d put it in line with the old vent, just so things would line up (and not look all diagonally janky until we patch that one down the line).

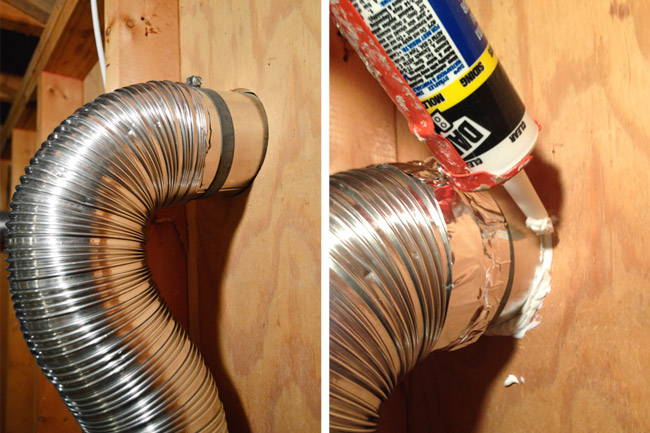

Back inside I trimmed off a bit of the vent pipe that stuck into the room and connected a semi-rigid vent pipe to it, complete with more metal faced duct tape and another ring of silicone caulk.

Then I just had to reattach the section of the stair that I had cut off and we were back in business. Well, I guess we need the dryer installed to truly be back in business – but you know what I mean.

We’ll take a brief interlude from duct talk to address the floor for a second, which you’ll notice is quite a bit lower in the new laundry room at the moment. We want the tile that’s going in there to be as flush with the hardwoods as possible, so we needed to build up the subfloor a bit.

I did some math and figured I’d need a 3/4″ layer of subfloor, a 1/2″ concrete backer board (for tiling on), plus the height of the tile & thinset to get myself flush with the hardwood floor. Since I wasn’t going to fit two 4 x 8′ pieces of subfloor in our car, I took this as my cue to rent the $19 Home Depot truck and get lots of my big materials – including all the drywall and insulation.

The 4 x 8′ pieces of 1/2″ OSB subfloor took a bit of trimming with my circular saw before bringing them up to the room, but all things considered it wasn’t too hard to get the two sheets to fit nicely, and then I glued and screwed them down (gluing can help cut down on any creakiness down the line). Here’s the first one going down.

Now let’s get back to ducts. This time we’re talking about the HVAC variety, since this new laundry room has zero heating or cooling coming its way… despite the main trunk line being so close (and the old laundry nook having its own dedicated vent).

I’m certainly not a pro in this department and I had a bit of trouble finding help online in this arena – but eventually this series had enough explanation and photos to give me the confidence to tackle it. Also, I noticed that Home Depot sold this “Add A Vent” kit – complete with materials, a tool list, and instructions. Perhaps this would be less scary than I expected?

Buuuuut… I didn’t actually use the Add-A-Vent box. After purchasing it (it was $67) I realized I already owned some of the items that were included, and that I could buy the others for about $54 instead. One of those items being this “Speedi-Boot” that makes nailing in the new ceiling vent between two joists really easy. So I just returned the boxed set and used my a-la-cart purchases (but wanted to call out that kit here in case it helps someone else who might not have some of the supplies I already did).

The part where I got nervous was cutting into my main HVAC trunk duct. But with some guidance from this post, I traced out where I wanted my new collar to attach…

…and used a utility knife to cut out the insulation, exposing the metal vent beneath.

The tutorial I was following didn’t really help me when it came to cutting the hole in the metal, but this video did. Basically I hammered a flathead screwdriver in to puncture it, then used my metal cutters to go around the circle. There are probably better snips for cutting holes than mine, but they did the trick well enough.

The collar has a ring of tabs on it, half of which I bent outward (to rest on the outside of the vent) while bending the others inward (to go into the hole). Once I placed it in the hole, I reached through the top of the collar and bent the inward tabs the other way so they held snugly against the inside of the vent.

Then I pressed some foil duct tape firmly around the whole thing to create a tight seal.

Next up was attaching the insulated flexible duct that would connect the collar to the ceiling vent. It’s pretty easy to cut to length using a utility knife, but you will need wire cutters to get through the inner wire coil. I held it in place with a zip tie, followed by more duct tape.

I used more zip ties to hang the flexible duct from the ceiling a bit so that it didn’t have any kinks or anything, since I didn’t want anything that might restrict airflow.

I’m gonna leave that cardboard “dust shield” (their words, not mine) in the ceiling vent until we’re ready to heat and cool this room, but I did quickly kick on the A/C just to make sure it worked. And in case you can’t tell by my thumbs up or cartoon air arrows, it did!

I realize that wasn’t the most fun post in the world, but I’m very glad to have gotten that stuff out of the way so this room can start to come together in more significant ways… like drywalling, which we have already started! It’s actually starting to look like a room in here.

But I’ll share all the drywall-hanging details when it’s done, which will hopefully be by Monday if all goes well. We’ve got book photoshoots today and tomorrow so we’re forced to switch our brains off Laundry Room Mode until Saturday, but at least we were able to get some laundry done at my parents house yesterday so we won’t be stinky for the photographer.

Joseph@littlehouseblue says

*stops reading to look at dryer duct plan picture*

Huh, I wonder why they didn’t just go straight out the back wall.

*reads next sentence*

Haha, ah I see you have anticipated my question.

Side note: I’ve been told another reason to have the crimped ends facing the same way as the airflow is so that lint doesn’t build up on that lip and cause a fire hazard.

YoungHouseLove says

So smart!

xo

s

Karen says

Great post! Just wondered whether you were concerned at all about the metal vent pipes being enclosed in the small stairs. Are there any guidelines on that? As is, how much airflow should there be around the vent? Thanks!

YoungHouseLove says

It’s all to code if those get covered with drywall (they often run through a wall behind drywall with insulation around them) although we think we might leave that attic steps and attic unfinished so they’re always out in the open.

xo

s

Sarah MC says

I love the detailed approach of this post! I followed the kitchen Reno in your last house with rapt attention, so I’m very excited to see these posts coming back.

Looking forward to the next installment!

Iryna says

Wow guys! Thanks so much for going into such detail on this! The stuff behind the walls always makes me nervous because of the “unknowns”, but this definitely helps!

Everett @ Palm Air Air Conditioning says

The new HVAC Vent installed their seems you guys did some brainstorming as it goes along with the dryer vent with raised floor. And yeah that Plan B, that was something. Cant wait to see the final pictures when you are ALL done.

Lindsey says

I just want to let you two know that I LOVE your blog,and one thing that makes it so amazing and relate-able are the “horribly punny references”. I like feeling like I could meet you and instantly be best friends. Please never stop with the cheese.

K. Stoker says

Keep in mind: when you eventually carpet the storage/attic space you might want to consult with an HVAC guy. The tonnage on your air conditioner is usually determined by square feet (among other factors) so your existing air conditioner might not be sized correctly for the added space. I don’t really think the laundry room addition is enough to mess it up though.

Ya’ll are doing a great job!

YoungHouseLove says

Thanks so much!

xo

s

Lee Ann says

So impressed how you think through all these steps. Thanks for sharing the process. (And have to say, I’m sure yours is probably the only home improvement DIY blog that uses the word “janky!” It’s for that kind of personality touch that I love what you guys write!)

lynne says

I am really enjoying watching this project unfold! Can’t wait to see what progress you make over the weekend. Loved how informative this post was while still being fun and interesting to read. I’m curious about the order of the next few steps. Will you try to completely finish the drywall before tiling the floor?

YoungHouseLove says

Yes, we have to insulate as we drywall and then mud/tape. Then it’s flooring and then trim.

xo

s

Amanda says

John, you’re always apologizing for the more technical/buildy posts being not exciting! I totally disagree. I think it’s really neat to see these sorts of projects tackled on your blog! While I enjoy reading about room makeovers and paint and accessories, I also really enjoy reading about total gut jobs that require a lot more technical know-how. I appreciate the time it took to document all of this (in addition to researching it all). I’m learning a lot. =)

Liz says

Are you guys thinking of adding a closet to the storage room so that you could classify it as an additional bedroom if you ever need to sell? I see on the floor plan that there is a space between Clara’s closet and the outside wall, but I don’t know if it would be big enough for a closet or not. Might be a nice feature – regardless of resale potential, it never hurts to have more closet space!

YoungHouseLove says

Someone else mentioned that and it’s really smart! Assuming it won’t take a big awkward bite out of the room we’d love to add one!

xo

s

Jenny says

This was a great post! We recently reno’d our kitchen, which included replacing an over-the-range microwave with a real range hood that vented outside. We’ve reno’d our entire house, but cutting a hole in the roof was by far the scariest thing we’ve ever done. Even scarier than leveling our basement floor with 1200 pounds of concrete, mixed in five gallon buckets. Luckily, both projects were successful on the first try. Thanks for all your DIY inspiration!

Jenni @ Cest Le Nest says

I have missed seeing these down and dirty posts from you guys. Thanks for all the detail! This is info I can use!

Leslie says

Great post! Good content. We’ll be doing some similar projects in the future, so I’m excited about this post!

Colleen says

I actually think these posts are very exciting!! I love watching you guys tackle the tougher part of home renovations, like drilling a dryer vent hole from the outside on a giant ladder, scary! Your blog has in the past, and still continues to give me the confidence to do the research and figure out just what I CAN do myself. Great post, you guys rock!

Jonia says

“The Mighty Ducts” hahahahaha! Love it!

Sherri says

Gosh, John- I am impressed with this project. It doesn’t look like a fun project at all, and it’s great that you are learning and educating yourself as you go along. You have to be pretty proud that you take on these challenges as they come to you. Does this rate right with the frustrating deck project from the last house? Or does this just seem to an outsider that the difficulty would be significant?

YoungHouseLove says

Deck was much harder! I would put these rerouting projects at a 4 on the difficulty scale (not very rigorous physically, and not too scary once you do a little research and think tings through). The deck and our first house’s bathroom gut-job were the hardest (both physically and mentally) but well worth it in the end.

-John

Natalie says

Great post! My husband and I are in a similar process right now. We are diving a large guest room into a master closet. This post is highly informative! I really like the new changes to your laundry room/rec room! It’ll be so worth it!

Kate Craig says

So when I saw the title, my first thought was breastfeeding, haha! You can tell I’m more Mommy than DIYer, so this was over my head, but you guys are inspiring!

YoungHouseLove says

So funny! Someone said that on Facebook too!

xo

s

Sassafras says

That hammertime photo on Instagram is hilarious!!! Go Daddy’s Grrrrl! Not that my vote counts but I TOTALLY vote anyway :) that hammertime and the one of Sherry pushing the stroller needs to go in your YEAR book. Along with one of your laundry room reno ones! Waiting for the Monday update!!! No pressure. Hahaha!!!!!

Robin says

How did you decide where to place the vent on the ceiling? Will it line up with anything or was it just random?

YoungHouseLove says

We had to put it between two joists and mainly wanted it out of the main sight line of the room, so that narrowed things down for us and we picked that spot.

-John

Christine says

You guys are amazing! I don’t know how you do it!

I also have to say the idea of putting the yellow paint on the vent and that is how you figured out where to cut…. BRILLIANT! I don’t know why I ever bother checking out other DIY sites because not only have you guys done it all but you have found the best ways to do it!

You guys just got me through a kitchen makeover this summer. I appreciate EVERY SINGLE POST.

Katie says

Ok, John…seriously…what can’t you do?? Majorly impressed over here. I think I’d be too nervous to attempt myself.